Understanding the Basics of Trenchless Technology

What Is Auger Boring?

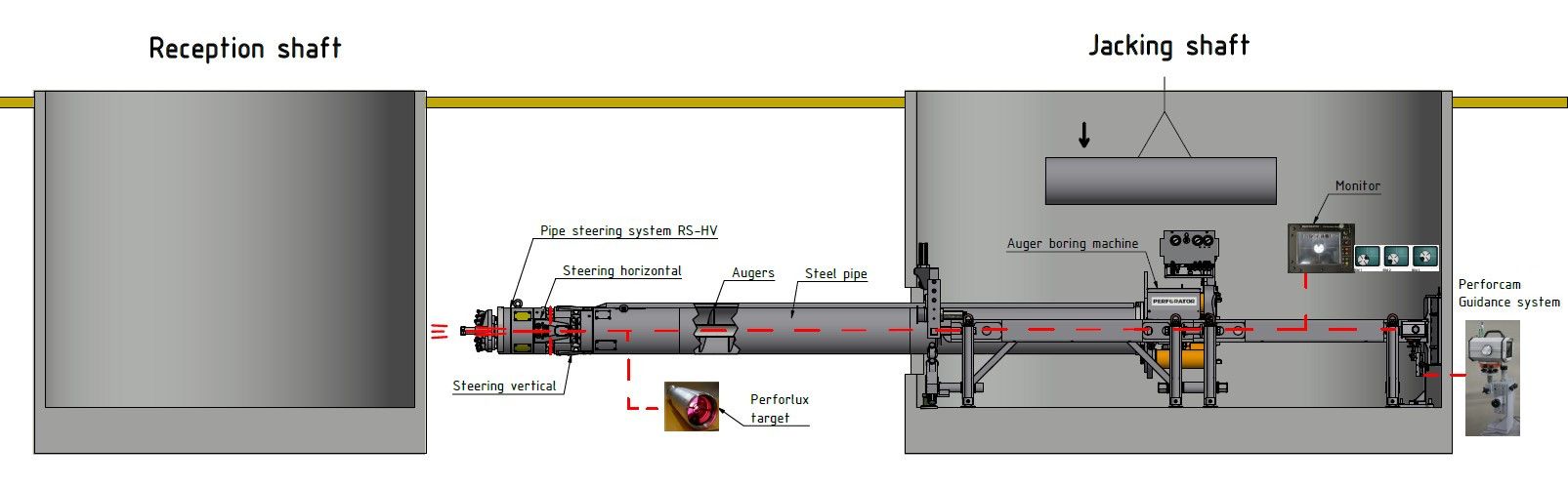

Auger boring is a trenchless method used to install steel casing under roads, railways, or structures without disturbing the surface. It uses a rotating auger inside a casing pipe to cut and remove soil as the pipe advances.

Key Characteristics

- Designed for straight-line, horizontal bores.

- Commonly used in utility crossings where minimal disruption is critical.

- Requires entry and exit pits.

- Best suited for stable soil types like clay, sand, or silty loam.

Pro Tip: Auger boring excels in short- to medium-length runs with large-diameter pipes. It’s ideal when steering precision isn’t required.

What Is Horizontal Directional Drilling (HDD)?

Horizontal Directional Drilling (HDD) is a steerable trenchless method used for installing pipelines and conduits along curved paths. It’s widely used in utility, telecom, and gas projects where surface disruption must be avoided.

How It Works

- Pilot Bore: A small-diameter drill navigates the planned path using tracking equipment.

- Reaming: The hole is enlarged by pulling back a reamer.

- Pipe Pullback: The final product pipe is pulled into place.

Key Features

- Supports long-distance installations (1000+ ft).

- Offers high directional accuracy.

- Works in diverse ground conditions, including rock.

- Requires drilling fluid (bentonite-based) to reduce friction and stabilize the borehole. View Our HDD Drilling Equipment

Comparing Auger Boring and HDD: Key Differences

Soil Conditions and Geology

Auger Boring

- Performs best in stable, cohesive soils such as clay, sandy loam, or silty soil.

- Struggles in rocky or shifting conditions—casing misalignment is a common risk.

HDD

- Engineered for diverse soil types, including rock, clay, gravel, and mixed formations.

- Drilling fluids help stabilise boreholes in weak or granular soils.

Pro Insight: If your project site includes hard rock or waterlogged conditions, HDD offers more flexibility and control than auger boring.

Project Length and Installation Depth

Auger Boring

- Practical bore length: 100–300 feet

- Max depth: typically 50–70 feet

HDD

- Can handle long bores exceeding 1000 feet

- Capable of working at depths beyond 100 feet with proper tracking and steering

Quick Tip: For longer pipeline installations or river crossings, HDD is often the only viable choice.

Accuracy and Steering Control

Auger Boring

- Non-steerable — limited to straight-line installations.

- Risk of drift if the soil is soft or inconsistent.

HDD

- Steerable with real-time tracking.

- Curve radius can be planned and adjusted mid-bore.

Why It Matters: If your installation needs to navigate around obstacles or follow a curved path, HDD is the clear winner.

Surface Disruption and Jobsite Footprint

Auger Boring

- Requires large entry and exit pits for jacking and spoil removal.

- May disrupt paved areas during pit construction.

HDD

- Minimal surface disruption — ideal for congested or sensitive areas (urban, ecological zones).

- Entry/exit pits are smaller and cleaner, especially when using mud recycling systems.

Speed and Mobilization

Auger Boring

- Faster to set up on simple jobs.

- Efficient for short distances with repeat setups.

HDD

- Requires more complex setup (tracking, mud system).

- Becomes more time-efficient on longer runs or multi-phase installations.

Summary Comparison Table

| Feature | Auger Boring | HDD (Horizontal Directional Drilling) |

|---|---|---|

| Soil Compatibility | Stable soils only | Most soils, including rock |

| Max Length | 300 ft | 1000+ ft |

| Steering Capability | None (straight only) | Fully steerable |

| Surface Disruption | High (requires pits) | Minimal |

| Ideal Applications | Road/rail crossings | Utility lines, telecom, river crossings |

| Setup Time | Quick for short bores | Slower startup, better long-term ROI |

When to Use Auger Boring vs. HDD: Project-Based Scenarios

Choosing the right trenchless method often comes down to jobsite constraints, installation goals, and risk tolerance. Below are clear examples that show when each method is most appropriate — giving contractors and project planners a practical decision-making framework.

Use Auger Boring When…

- Your installation path is straight

- Auger boring is ideal when the bore does not require steering.

- Common in municipal or DOT projects with short, direct crossings.

- You’re working with stable, predictable soil

- Best for dry, firm ground conditions where soil won’t collapse during boring.

- Space is available for pits

- Entry and exit pits are required for auger boring.

- It’s most efficient when open work zones are available.

- Large-diameter steel casing is required

- Auger boring excels at installing large-diameter pipe with precision.

Real-World Example

- A 36" steel pipe is being installed under a highway. A short, straight crossing with open workspace on both sides makes auger boring the most cost-effective and reliable solution.

Use Horizontal Directional Drilling (HDD) When…

- The route is curved or passes around obstacles

- HDD is perfect for navigating around utility corridors, tree roots, or existing infrastructure.

- You need to minimize surface disruption

- Ideal in urban environments, wetlands, or private property where open trenching isn’t feasible.

- The bore length exceeds 300 feet

- HDD handles long-distance installs efficiently, especially with preplanned entry/exit paths.

- You’re dealing with complex or rocky soils

- Drilling fluids and steerable heads give HDD a technical edge in challenging ground conditions.

Real-World Example:

- A fiber optic line must run 600 feet beneath a residential neighborhood with driveways, trees, and underground gas lines. HDD is used to precisely steer under these obstacles with minimal disruption.

Equipment Considerations for Each Method

Selecting the right trenchless installation method isn’t just about soil and distance — it’s also about having the right machine for the job. Whether you’re choosing auger boring or HDD, equipment compatibility, performance, and reliability play a key role in project success.

This section highlights the specific machines and accessories used for each method, with internal links to Wolf Machinery’s offerings to drive qualified traffic.

Auger Boring Equipment Essentials

Key Machine Features

- Thrust and rotation capacity suitable for the required pipe diameter and length

- Hydraulic power packs for consistent torque

- Spoil removal systems for clean bore paths

- Heavy-duty frames for pit-mounted operations

Common Applications

- Steel casing installation for sewer, water, or sleeve pipes

- Projects under highways or railway embankments

Recommended Equipment Examples

- Auger Boring Machines – 24" to 72"+ capacity

- Casing attachments with hydraulic augers

HDD Equipment Requirements

Core Components

- Directional drilling rig with hydraulic thrust/pullback systems

- Drill rods and reamers for pilot and enlarging bores

- Tracking systems (e.g., DigiTrak or Subsite) for steering

- Mud mixing and recycling systems to manage drilling fluids

Ideal Use Cases

- Utility installations where accuracy and surface preservation are critical

- Long-distance, curved installations in mixed soils or urban areas

Featured HDD Solutions

- Compact rigs for residential or telecom bores

- Mid-size rigs with 20,000–40,000 lbs thrust for infrastructure jobs

Auger Boring vs. HDD Equipment Table

| Equipment Feature | Auger Boring | HDD |

|---|---|---|

| Pipe Size Compatibility | Large-diameter steel casing | Small to medium pipe diameters |

| Steering System | None (straight path) | GPS-tracked directional system |

| Fluid Management | Not required | Requires drilling fluid system |

| Site Setup | Entry & exit pits | Small entry, remote exit |

| Maintenance Needs | Moderate (mechanical wear) | High (fluid system, tracking tech) |

Need Help Choosing the Right Equipment?

Let Wolf Machinery help you match your next job with the right equipment.

Call-to-Action:Request a Consultation or Quote

Cost Comparison and Long-Term ROI

While both auger boring and HDD can be cost-effective in the right scenarios, their upfront costs, operational expenses, and long-term return on investment (ROI) differ significantly. This section will help contractors and project planners understand where the real value lies — not just in equipment costs, but in project efficiency and jobsite impact.

Upfront Equipment & Setup Costs

Auger Boring

- Generally lower equipment cost than HDD

- Requires additional setup for entry and exit pits

- Fewer moving parts → lower maintenance cost

HDD

- Equipment is more complex and higher initial investment

- Requires tracking systems, fluid systems, and trained operators

- Setup time is longer, but scalable over multiple bores

Quick Note: For projects with frequent, short bores — auger boring offers faster ROI due to lower capital requirements.

Labor & Operational Efficiency

Auger Boring

- Smaller crew needed, but manual spoil removal can be time-consuming

- Pits must be dug and secured for each bore

- Slower on long-distance jobs

HDD

- Requires trained HDD operator and support crew

- Automated systems allow continuous boring with minimal downtime

- Greater efficiency in multi-phase or utility corridor installations

Downtime, Disruption & Remediation

Auger Boring

- Site restoration can add cost (especially with deep pits)

- Risk of line deflection in poor soils → costly corrections

HDD:

- Minimal disruption = lower post-installation restoration cost

- Accurate steering → fewer installation issues

- Better suited for tight regulatory environments (e.g., urban, environmental)

Long-Term ROI: Which Method Pays Off?

| Factor | Auger Boring | HDD |

|---|---|---|

| Equipment Cost | Lower | Higher |

| Speed on Long Bores | Slower | Faster |

| Accuracy | Basic (no steering) | High-precision tracking |

| Disruption to Environment | More | Minimal |

| Versatility | Limited (straight lines only) | High (curves, utilities, rivers, etc.) |

Conclusion

- Choose Auger Boring if you're doing frequent, short, straight-line bores under roads or rail.

- Choose HDD for longer runs, complex paths, or sensitive surface areas where non-invasive precision saves time and money.

Pro Tips for Choosing the Right Method

Choosing between Auger Boring and Horizontal Directional Drilling (HDD) is more than a technical decision — it’s about understanding your jobsite conditions, project goals, and risk tolerance.

Start with a Detailed Site Assessment

Before deciding on a boring method, assess:

- Soil type (use a geotechnical report if possible)

- Length and depth of the required installation

- Presence of obstacles (utilities, trees, foundations)

- Surface constraints (urban areas, paved roads, sensitive zones)

Pro Tip: If your path isn't straight or you expect to hit mixed soils, lean toward HDD for flexibility.

Consider Permit and Environmental Factors

Some municipalities or DOTs may

- Restrict open pit construction (making auger boring less ideal)

- Require low-disturbance methods (favoring HDD)

- Demand fluid containment and tracking systems (relevant for HDD compliance)

Think in Terms of Crew Capability

- Do you have trained HDD operators and tracking techs?

- Can your team handle fluid recycling and equipment maintenance?

- For smaller outfits or time-sensitive jobs, auger boring may be more manageable.

Pro Insight: Complex equipment is only valuable if your team can run it safely and efficiently.

Match the Method to Pipe Material and Diameter

| Pipe Material | Auger Boring | HDD |

|---|---|---|

| Steel casing | Ideal | Suitable |

| HDPE conduit | Not ideal | Ideal |

| PVC or ductile | Limited | Ideal |

Note: Auger boring may damage lightweight pipes if not properly supported — best reserved for steel casing or encasement sleeves.

Use This Quick-Select Method Checklist

Use Auger Boring if

- Bore is short (<300 ft) and straight

- Soil is firm and consistent

- You have easy access for pits

- You're installing steel casing under a roadway

Use HDD if

- The bore needs to curve or steer around obstacles

- You're in an urban or sensitive environment

- You need a longer run (>300 ft)

- You're installing telecom, gas, or water lines in varied soils

Contact Wolf Machinery for Equipment Advice

Final Verdict – Which Method Is Right for You?

Both Auger Boring and Horizontal Directional Drilling (HDD) have proven track records in trenchless utility installation. But the best method for your underground project depends on the jobsite, not the technology.

When Auger Boring Makes Sense

Choose auger boring when

- You’re working with stable soils in a straight-line path

- You have access for entry/exit pits

- You’re installing large-diameter steel casing

- The bore is short-to-medium length, typically under 300 feet

Strengths: Lower cost, straightforward setup, excellent for heavy-duty casing installs

When HDD Is the Better Fit

Use HDD when

- The path involves curves or underground obstacles

- You’re operating in urban, residential, or environmentally sensitive areas

- You need long-distance installation or minimal surface disruption

- Your crew is trained on fluid management and tracking systems

Strengths: Steerability, longer runs, less surface impact, adaptable to many pipe types

Making the Smart Choice

Contractors who select the right method from the start save on:

- Costly delays

- Remobilization and rework

- Environmental remediation

- Equipment downtime

Pro Insight: A successful bore isn’t just about getting the pipe through — it’s about doing it safely, cleanly, and profitably.

Talk to the Experts at Wolf Machinery Supply

Still unsure which method fits your next project? Wolf Machinery Supply offers

- Equipment recommendations based on your job specs

- In-stock auger boring machines and HDD rigs

- Technical support from real industry pros

Contact us today to get matched with the right trenchless solution or request a quote for the equipment that fits your soil, scope, and timeline.

FAQs – Auger Boring and HDD

Auger boring uses a rotating auger inside a steel casing to push through soil in a straight line, typically for short-distance utility crossings under roads or railways. HDD (Horizontal Directional Drilling) is a steerable method that uses a tracked drill head to navigate curved paths underground — ideal for longer runs, complex soil conditions, and minimal surface disruption.

HDD usually has a higher upfront equipment and setup cost compared to auger boring. However, it may provide better long-term value on complex jobs by reducing surface restoration costs, shortening project timelines, and enabling longer, curved installations that auger boring can’t handle.

No. Auger boring performs best in cohesive, stable soils like clay or sandy loam. It’s not recommended for rocky or loose ground, as misalignment and spoil removal issues can occur. In such conditions, HDD or microtunneling methods are more suitable.

Use HDD when the project requires: Steering around obstacles Long-distance pipe installation Minimal surface disturbance Operation in mixed or unstable soil It’s especially useful in urban areas, residential neighborhoods, and environmentally sensitive zones.

Auger Boring: Best for steel casing or encasement sleeves HDD: Compatible with HDPE, PVC, ductile iron, and steel — especially for continuous pulls or curved paths Always consult your equipment provider about pullback ratings and material stress limits.

Auger Boring: Typically effective up to 50–70 feet in depth HDD: Can exceed 100+ feet, depending on the machine size, tracking system, and soil stability Depth capabilities also depend on bore length and available access for setup.