What is Auger Boring?

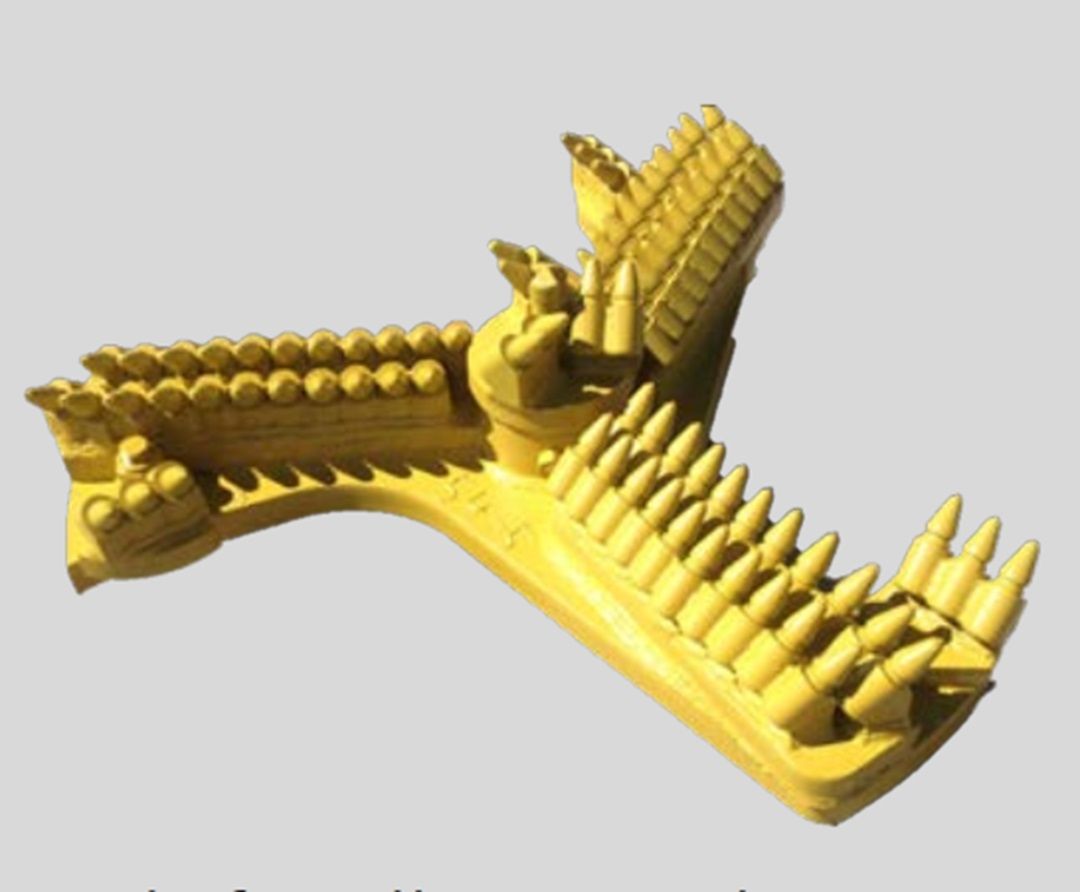

Auger Boring is a trenchless construction method used to install underground pipes and conduits by drilling a horizontal hole. A rotating auger inside a steel casing removes the soil as the pipe is pushed through the ground.

Utility Installations – Used for laying water, sewer, gas, and telecom lines under roads, railways, and buildings.

Projects Needing Minimal Surface Disruption – Ideal for urban areas where open trenches are not possible.

Hard and Stable Soils – Works best in clay, sand, and gravel, but less effective in rock formations.

Ground Collapse – Loose soil or unstable ground can cause borehole failure.

Misalignment – The bore path may shift, leading to incorrect pipe placement.

Casing or Auger Stuck – Happens when encountering hard obstructions or poor lubrication.

The auger slows down or stops unexpectedly.

The borehole starts collapsing, causing uneven pipe placement.

Increased wear and tear on equipment, leading to higher costs and delays.

Soil Testing – Always check ground conditions before drilling.

Proper Lubrication – Reduces friction and prevents equipment damage.

Precision Guidance Systems – Helps keep the bore on track.

Auger boring is a cost-effective and efficient method for underground installations, but proper planning and soil analysis are key to avoiding costly mistakes.