What is Tunneling?

Tunneling is the process of digging underground passages for transportation, utilities, and infrastructure projects. It is used to build roads, railways, pipelines, and sewer systems without disrupting surface activity.

Transportation – Builds tunnels for trains, highways, and subways to improve travel.

Utility Installations – Used for water, gas, electricity, and communication lines.

Mining & Construction – Helps access underground resources like minerals and oil.

Ground Collapse – Weak or unstable soil can cause tunnels to cave in.

Water Infiltration – Underground water leaks can weaken tunnel structures.

Equipment Malfunctions – Drilling machines and boring tools can fail due to rough conditions.

Cracks or shifting in tunnel walls indicate instability.

Excessive vibration or noise from machinery signals equipment strain.

Unexpected water leaks show poor sealing or weak ground conditions.

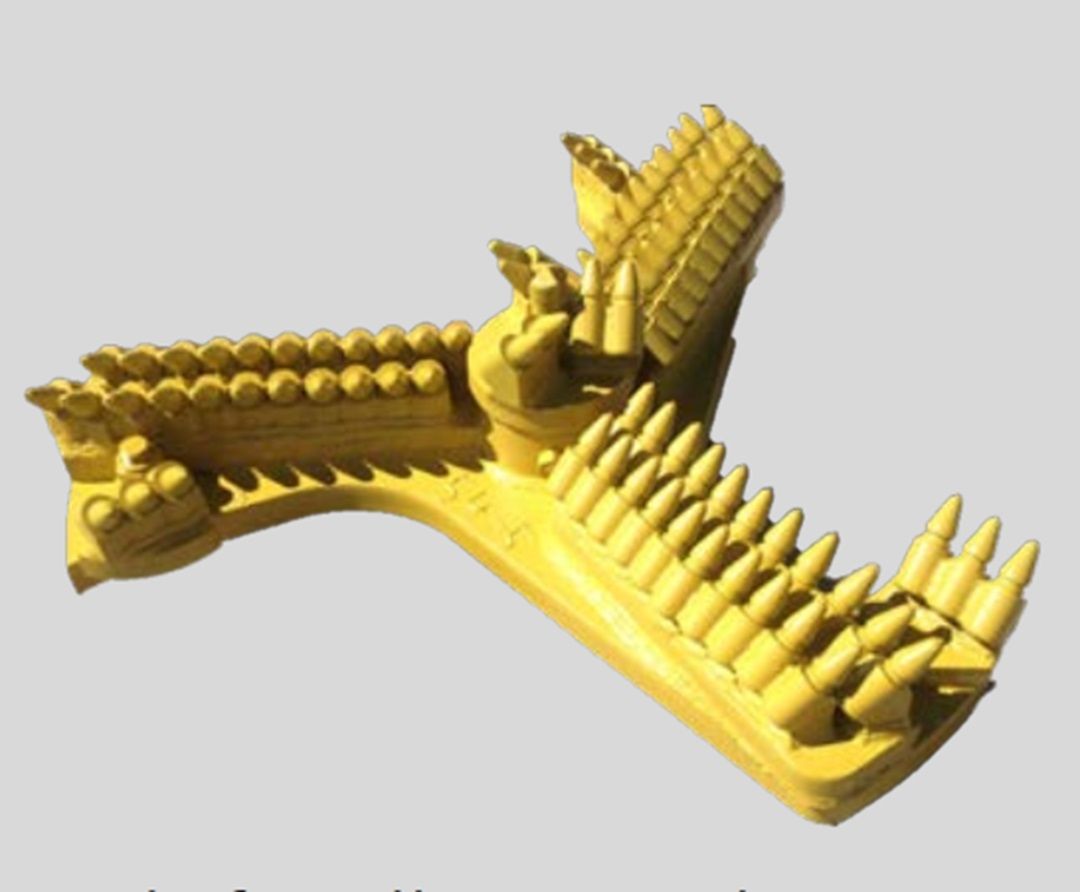

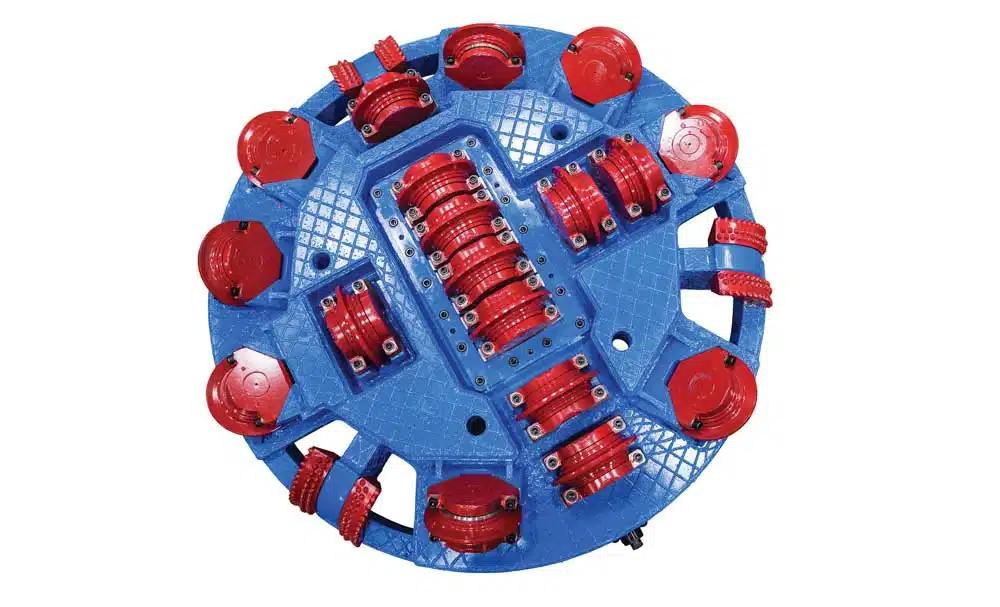

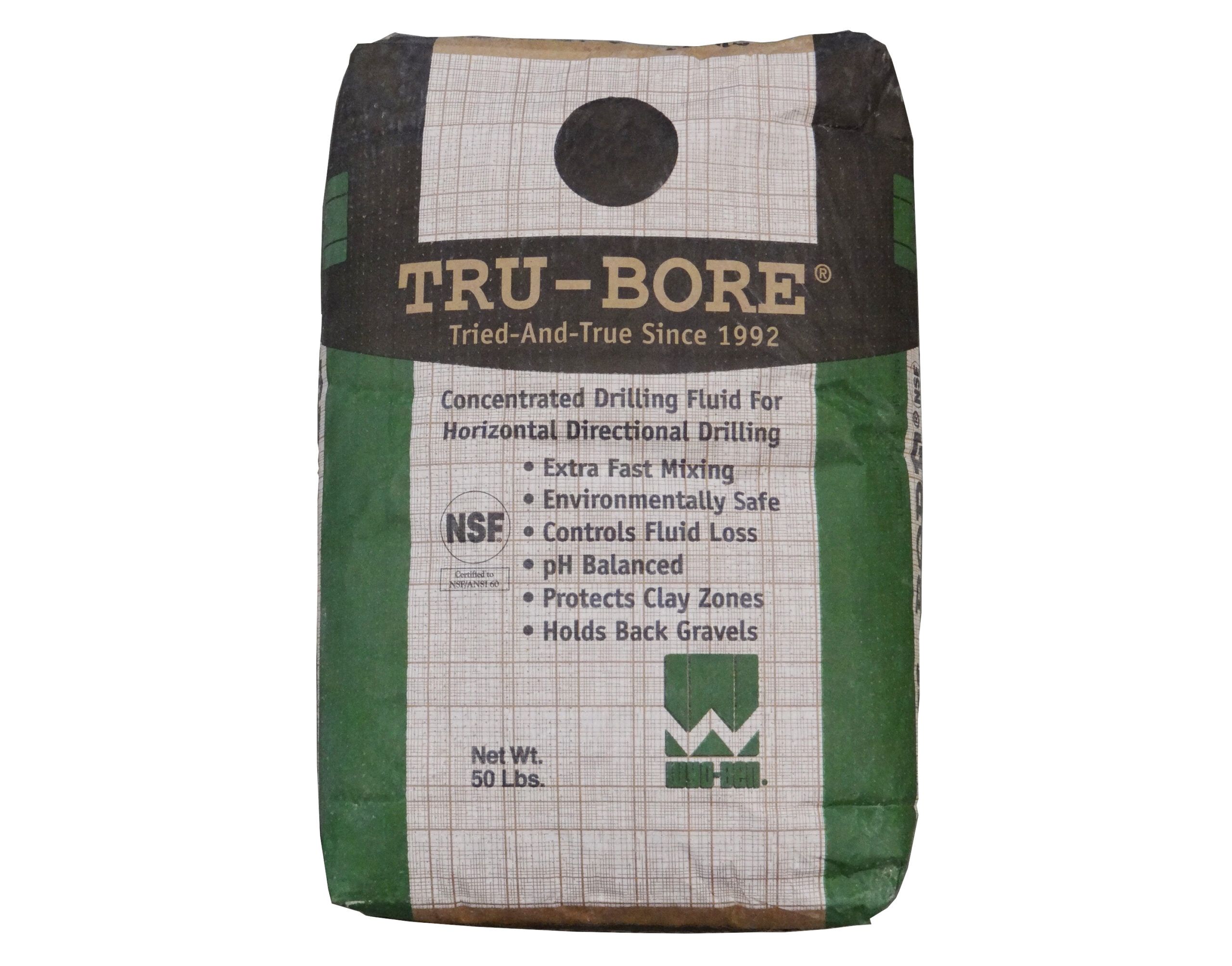

Use Advanced Drilling & Boring Machines – Ensures precision and stability.

Proper Ground Analysis – Helps prevent collapses and unexpected water flow.

Regular Equipment Maintenance – Reduces downtime and improves efficiency.

Using the right tunneling equipment ensures safe, efficient, and cost-effective underground construction. High-quality pipe jacking machines, tunnel boring machines (TBMs), and rock drilling rigs help prevent delays and costly repairs.